An overview of laminated glass

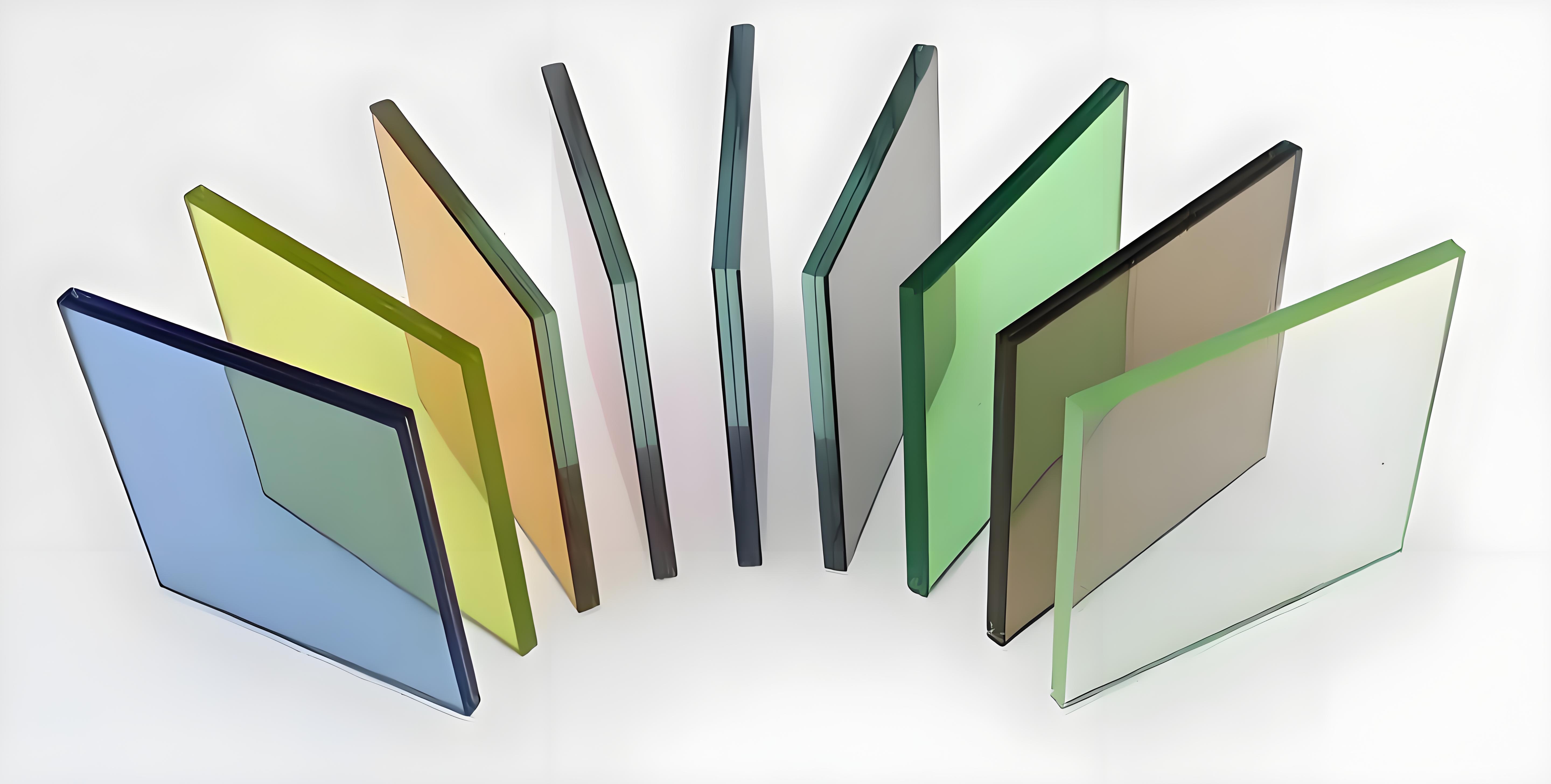

Laminated glass is composed of two or more pieces of glass, sandwiched between one or more layers of organic polymer intermediate film, after special high temperature prepressing (or vacuum) and high temperature and high pressure process treatment, so that the glass and the intermediate film permanently bonded as one of the composite glass products. Commonly used laminated glass intermediate film are :PVB, SGP, EVA, PU and so on.

17

2025-02

Tempered glass is actually a kind of prestressed glass, in order to improve the strength of the glass, usually use chemical or physical methods, the formation of compressive stress on the surface of the glass, the glass to withstand external forces first offset the surface stress, thereby improving the bearing capacity, enhance the glass itself resistance to wind pressure, cold and heat, impact and so on.

17

2025-02

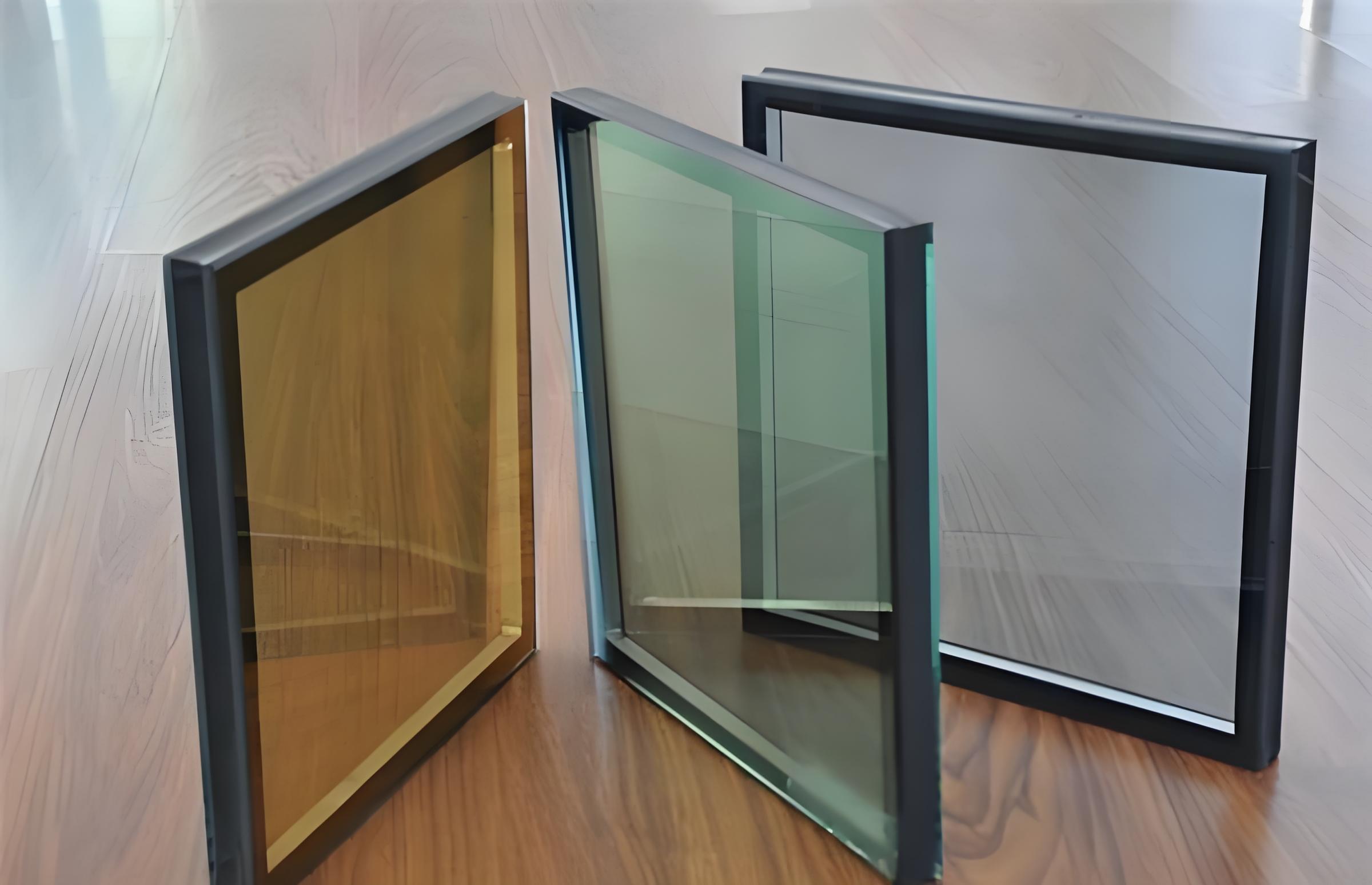

Characteristics of insulating glass

The two (or three) pieces of glass, the use of high strength and high air tightness composite binder, the glass sheet and the aluminum alloy frame containing the desiccant bond, made of high-efficiency sound insulation glass.

17

2025-02

What are the characteristics of water heater panel glass processing?

The appearance of ordinary gas water heaters is usually Made of metal. Due to the need for aesthetics, the desired pattern is printed on the metal surface shell by screen technology. In order to increase aesthetics, a glass panel is added on the main surface of the metal surface shell of the gas water heater, but how to fix the glass panel becomes a problem. One method is to use fixing parts, such as screws or stainless steel rods; the other is to use double-sided tape to stick the glass on the metal shell. The above three solutions have the following problems Water heater panel glass processing

28

2022-07

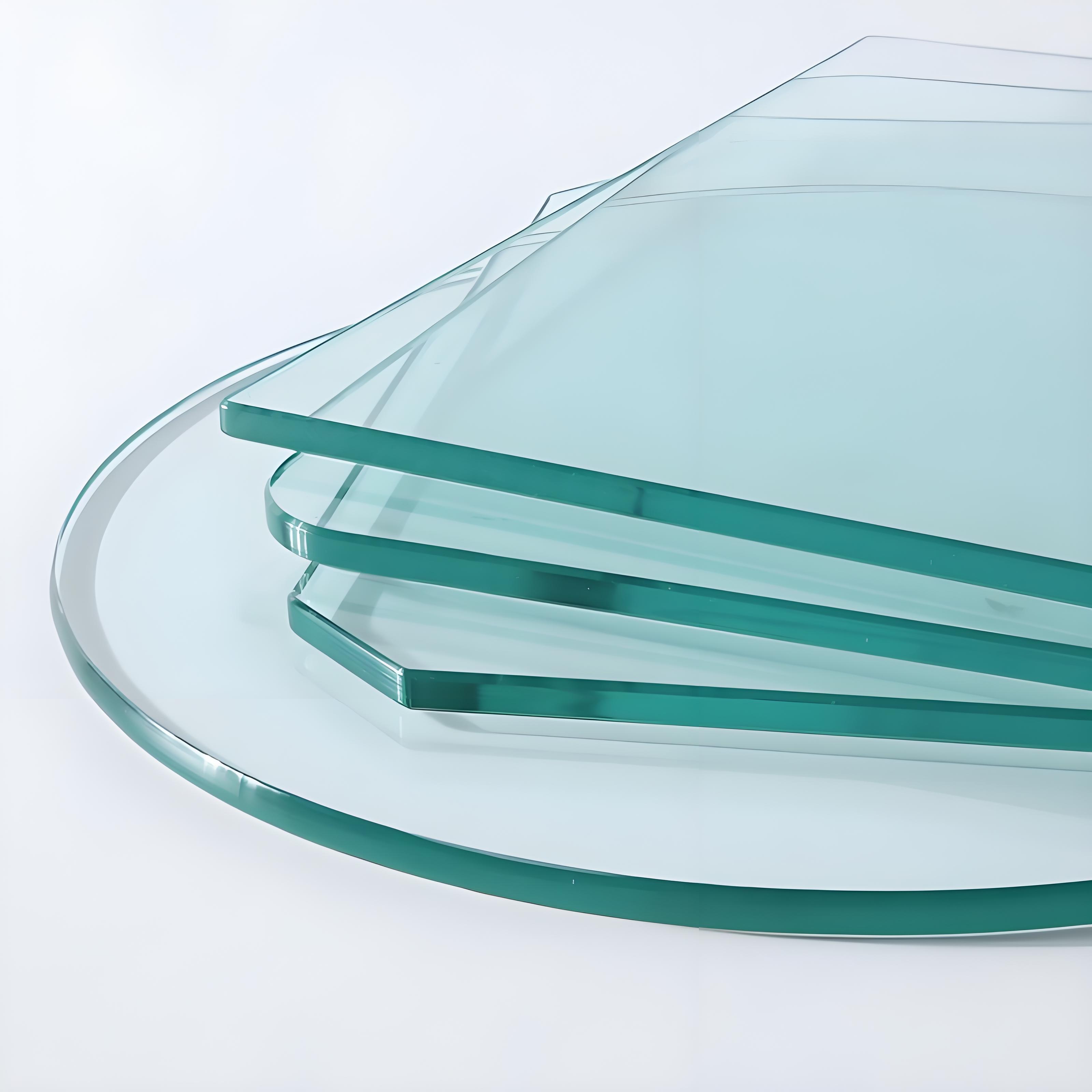

What is the thickness of laminated glass in millimeters?

What is the thickness of laminated glass in millimeters? Laminated glass is an architectural glass produced by placing two or more liters of glass into a polyvinyl butyraldehyde (PVB) element and then heating it to the temperature at which the PVB is fused with the glass. This process makes a stronger and more durable product than ordinary glass typically used for windows.

10

2022-01